This case study will showcase how Systemiser was used as the single integrated workplace for working with complex circular economy systems. It was used to map and analyse the production planning problem of Total Green and develop a strategy and prototype planning solution called OptiPlan.

The 9-minute video below demonstrates how Systemiser and OptiPlan can potentially be used to maximise value from other circular economy systems. A 3-minute read below summarises the study.

Total Green Recycling and their Production Problem

Total Green Recycling (TGR) is an IT asset recovery facility in Western Australia. Total Green’s electronic waste facility refurbishes reusable assets such as computers and phones, salvages reusable parts, and recycles materials.

Total Green’s mission is to put a stop to the flow of e-waste to landfills. The recovered materials are redirected into productive, profitable, green enterprise solutions. They support local communities with purposeful employment and education. They strive to clean our environment and reduce carbon emissions, one electronic device at a time.

The Production Problem

Michael, the founder and director, had a problem. The variability of inflow makes it hard to decide which assets are most profitable to refurbish. Stop-start bottlenecks in the value chain reduce production and profitability. It’s hard to keep finding the best production plan for each shift and longer-term planning.

Michael, the founder and director, had a problem. The variability of inflow makes it hard to decide which assets are most profitable to refurbish. Stop-start bottlenecks in the value chain reduce production and profitability. It’s hard to keep finding the best production plan for each shift and longer-term planning.

Total Green, like many circular economy businesses, has to manage a facility affected by:

- Supply Variability,

- Changing Prices,

- System Constraints,

- Variety of Assets & Processes,

- Production Bottlenecks.

Total green needed help optimising its production plans to meet these challenges and maximise their positive impact within the community. The OptiPlan prototype solution maximises profit and minimises costs and bottlenecks within the system constraints.

Solution Teamwork

Holonic and Systemiser teamed up with Michael to help Total Green strategise for a growing circular economy network and to address Michael’s production planning problem.

Systemiser and Holonic have specialist know-how in the relevant areas of: circular economies, systems engineering, planning, simulation, and optimisation. Michael and his managers had the knowledge of the systems and processes needed by the team to design and develop the OptiPlan prototype solution.

Analysing the Problem

We started by adding popular canvases to the Systemiser map so that we could understand Total Green’s strategy and objectives. Andy, from Holonic, introduced the Circular Economy and Partnership canvases, together with the Three Horizons Canvas. The mapped canvases enabled us to see how Total Green could best transition the wasteful make-use-dispose of IT assets to a circular economy.

You can view and get started with a template within Systemiser by using the link below. If you aren’t already a user then please head to our Get Started page to sign up for free.

The OptiPlan Proof of Value Solution

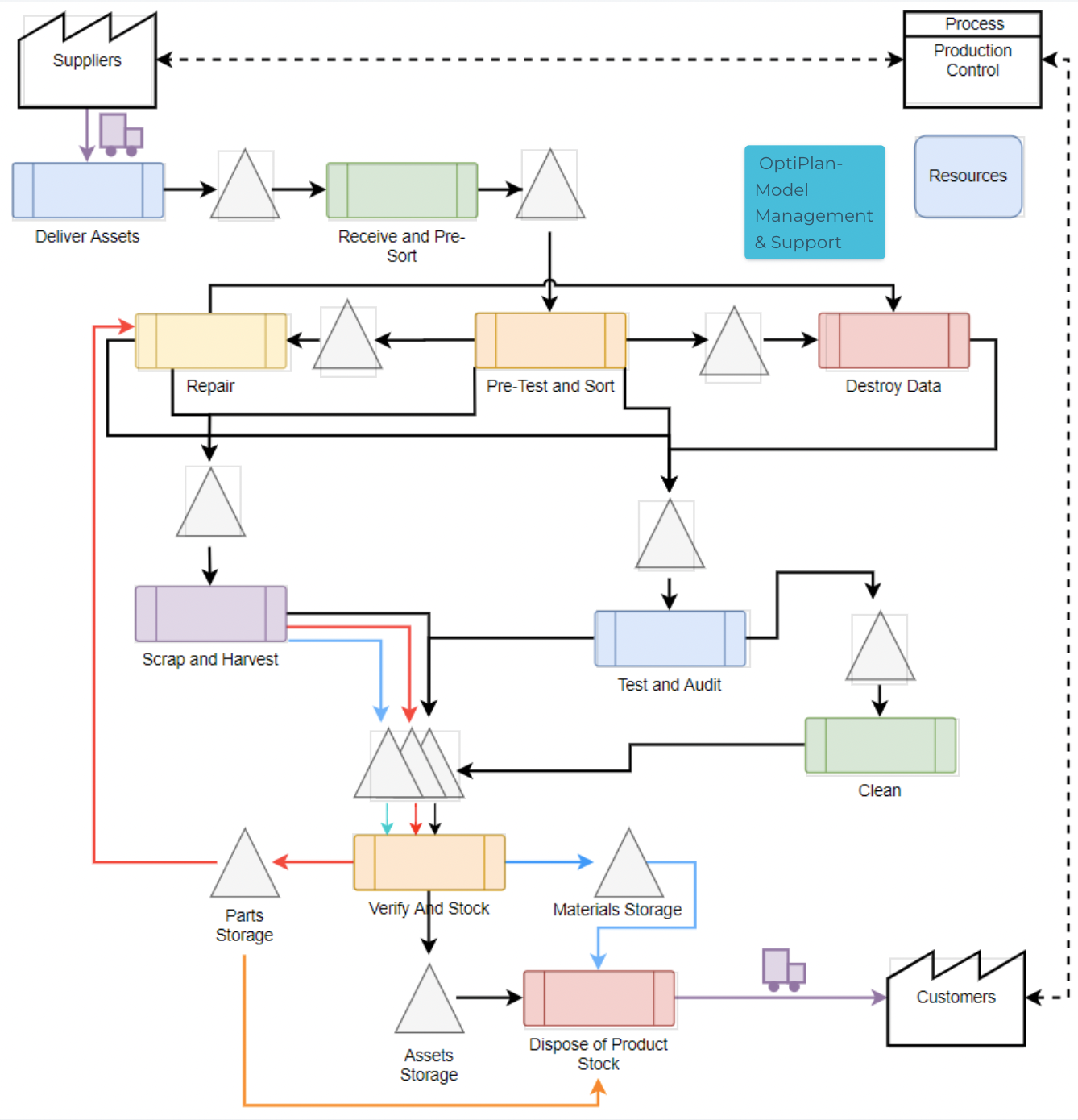

We added a new canvas to Systemiser's one map to conceptually explain Total Green’s value chain processes and OptiPlan’s planning processes.

The value chain starts with the suppliers of disposed IT assets and ends with the customers of refurbished assets, reusable parts and recycled materials. The video shows how the canvas overview opens up and explains the underlying detailed factory processes and intelligent thinking processes of OptiPlan.

Systemiser's Value Proposition

Some features and benefits of Systemiser and OptiPlan:

- Systemiser’s one map was used to map the processes of Total Green and Optiplan’s autonomous planning processes. The map provides a clear mental model of the complexities for common understanding and decision making.

- Systemiser also has an integrated development environment for leveraging spreadsheet models with Python code. Optiplan was developed inside the one map by coding the systematised knowledge in the mental model that everyone understands.

- Managing change to mental models and computer models, in the one map, makes it easy to synchronise remote and local knowledge work, system change and OptiPlan upgrades.

OptiPlan's Value Proposition

OptiPlan effectively uses a digital twin of Total Green to quickly find the best possible production and resource plan. Input data from Total Green’s ERP and other data sources is used to re-optimise plans.

Optiplan minimises the time it takes to reestablish the maximum the flowrate of profit when reality changes the plan

Reality never goes according to plan during the shift, tactically, and strategically. Value is lost while the plan is wrong. Optimising sub-systems and processes often sub-optimises the system. Optiplan’s value proposition is reducing the time it takes to find and reestablish the maximise the flowrate of profit for the whole of the system.

The outputs from Optiplan include:

- Rostering and allocating workers within the facility,

- Prioritising and scheduling supplier deliveries to keep the factory producing at maximum capacity and profitability,

- Scheduling tasks that produce the greatest profit from available resources,

- Managing the process resourcing and buffer levels so that bottlenecks are minimised and productivity is maximised.

Systemiser and OptiPlan Teamwork

The video demonstrates how Systemiser provided the one map and the integrated development environment for design and development of a Total Green prototype solution. A full feature OptiPlan for optimising a more complex network of multiple facilities and partners is envisaged for the future.

Please register and start systemising with our free version. A systemised map of your system will help us see how we can reuse, repurpose, and circulate OptiPlan knowledge to maximise the value output from your system of interest.

"The OptiPlan prototype demonstrated a more productive way for us to work. We see the potential of OptiPlan’s resource and production planning as part of our growth strategy."

~ Michael Coghill - Founder & Director of Total Green Recycling

totalgreenrecycling.com.au

“Systemiser is like a circular economy for reusable know-how and expertise. It nurtures ‘knowledge communities’ to think systematically and share ideas and resources. It empowers collaboration, communication and collective intelligence to solve systemic problems.”

~ Andy Thomson - Founder holonic.com.au